Mai yankan niƙa mai inganci na iya kammala aikin sau uku na kayan aikin yau da kullun a cikin adadin lokaci ɗaya yayin da rage yawan kuzari da kashi 20%. Wannan ba nasara ba ce kawai ta fasaha, amma har ma da tsarin rayuwa don masana'antu na zamani.

A cikin bita na injuna, sauti na musamman na masu yankan niƙa masu juyawa da ke zuwa cikin hulɗa da ƙarfe shine ainihin waƙar masana'anta na zamani.

Wannan kayan aiki mai jujjuyawa tare da yankan gefuna da yawa suna siffanta komai daga ƙananan sassan wayar salula zuwa ƙaƙƙarfan tsarin jirgin sama ta hanyar cire abu daidai daga saman aikin.

Yayin da masana'antar kera ke ci gaba da haɓakawa zuwa daidaici da inganci, fasahar milling cutter tana fuskantar juyi shuru - injin injin bionic milling wanda fasahar bugu na 3D ke ƙera shine 60% mai sauƙi, amma tsawon rayuwarsa ya ninka fiye da ninki biyu; rufin yana ƙara rayuwar kayan aiki ta hanyar 200% lokacin sarrafa kayan zafi mai zafi.

I. Milling kayan yau da kullum: ma'anar da ainihin ƙimar

Abin yankan niƙa kayan aiki ne mai jujjuyawa tare da hakora ɗaya ko sama da haka, kowannensu a jere kuma yana cire kayan aikin. A matsayin babban kayan aiki a cikin niƙa, yana yin ayyuka masu mahimmanci kamar injina jiragen sama, matakai, tsagi, kafa saman, da yanke kayan aiki.

Ba kamar yankan maki ɗaya ba a cikin juyawa, masu yankan niƙa suna haɓaka ingantaccen injina ta hanyar yanke a wurare da yawa a lokaci guda. Ayyukan sa kai tsaye yana rinjayar daidaiton aikin aikin, ƙarewar saman, da ingancin samarwa. A cikin filin sararin samaniya, babban abin yankan niƙa na iya adanawa har zuwa 25% na lokacin samarwa yayin sarrafa sassan tsarin jirgin sama.

A cikin masana'antar kera motoci, madaidaicin nau'in injin niƙa kai tsaye suna tantance daidaitattun abubuwan haɗin injin.

Babban darajar masu yankan niƙa ta ta'allaka ne a cikin cikakkiyar haɗin haɗin kai da inganci. Daga saurin cire kayan a cikin roughing zuwa saman jiyya a cikin kyakkyawan machining, waɗannan ayyuka za a iya kammala su akan kayan aikin injin guda ta hanyar canza masu yankan niƙa daban-daban, rage saka hannun jari na kayan aiki da samar da canjin lokaci.

II. Halin tarihi: juyin fasaha na masu yankan niƙa

Tarihin ci gaba na masu yankan niƙa yana nuna canje-canjen fasaha a cikin masana'antar kera injina gabaɗaya:

1783: Injiniyan Faransa René ya kirkiro mai yankan niƙa na farko a duniya, yana buɗe sabon zamani na yankan juzu'i mai yawan haƙori.

1868: Tungsten alloy tool karfe ya samo asali, kuma saurin yanke ya wuce mita 8 a minti daya a karon farko.

1889: Ingersoll ya ƙirƙira mai yankan masarar masara mai juyi (spiral milling cutter), yana sanya ruwan wuka a cikin jikin mai yankan itacen oak, wanda ya zama abin kwatancen mai yankan masara na zamani.

1923: Jamus ta ƙirƙira siminti carbide, wanda ya ƙara saurin yankewa fiye da sau biyu na ƙarfe mai sauri.

1969: An ba da takardar izini don fasahar tururi da aka yi amfani da shi, yana haɓaka rayuwar kayan aiki da sau 1-3.

2025: Metal 3D-buga bionic milling cutters cimma wani 60% nauyi rage nauyi da ninka tsawon rayuwarsu, karya ta hanyar gargajiya yi iyakoki.

Kowace ƙirƙira a cikin kayan aiki da sifofi suna haifar da haɓakar geometric a ingancin niƙa.

III. Cikakken bincike na rarrabuwa mai yankan milling da yanayin aikace-aikace

Dangane da bambance-bambancen tsari da aiki, ana iya raba masu yankan niƙa zuwa nau'ikan masu zuwa:

| Nau'in | Halayen tsari | Abubuwan da suka dace | Masana'antar Aikace-aikace |

| Ƙarshen niƙa | Yanke gefuna a duka kewaye da fuskokin ƙarshe | Tsagi da sarrafa saman mataki | Samfuran ƙira, injina gabaɗaya |

| Face milling abun yanka | Babban diamita na ƙarshen fuska mai yawan ruwan ruwa | Manyan niƙa mai saurin sauri | Mota Silinda block da akwatin sassa |

| Gefe da fuska milling abun yanka | Akwai hakora a bangarorin biyu da kewaye | Daidaitaccen tsagi da sarrafa mataki | Toshe bawul na hydraulic, dogo mai jagora |

| Ƙarshen ƙwallon ƙwallon ƙafa | Ƙarshen yankan hemispherical | 3D saman aiki | Ruwan jirgin sama, cavities mold |

| Mai yankan masara | Karkace tsari na abun da ake sakawa, babban guntu sarari | Niƙa mai nauyi a kafaɗa, zurfin tsagi | Sassan tsarin sararin samaniya |

| Saw ruwa niƙa abun yanka | Yanke bakin ciki tare da hakora da yawa da kusurwoyi na biyu na karkacewa a ɓangarorin biyu | Zurfafa tsagi da rabuwa | Yanke bakin ciki tare da hakora da yawa da kusurwoyi na biyu na karkacewa a ɓangarorin biyu |

Nau'in tsari yana ƙayyade tattalin arziki da aiki

Hadin kaiabin yankan niƙa: Jiki mai yankewa da hakora an kafa su gaba ɗaya, tare da tsattsauran ra'ayi mai kyau, wanda ya dace da ƙananan ƙayyadaddun mashin ɗin diamita.

Masu yankan milling ɗin da za a iya ƙididdige su: canji mai inganci na abubuwan sakawa maimakon duka kayan aiki, dace da roughing

Abun yankan niƙa mai walda: tip ɗin carbide wanda aka saƙa zuwa jikin karfe, mai tattalin arziki amma iyakanceccen lokacin sake niƙa

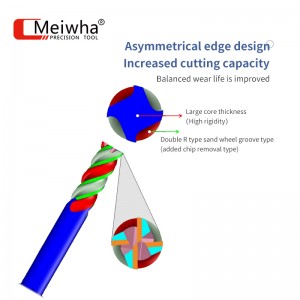

Tsarin bionic bugu na 3D: ƙirar saƙar zuma na ciki, rage nauyi 60%, ingantaccen juriya

IV. Jagoran Zaɓin Kimiyya: Maɓallin Maɓalli Madaidaicin Bukatun Gudanarwa

Zaɓin abin yankan niƙa kamar likita ne ya rubuta takardar sayan magani - dole ne ka rubuta maganin da ya dace don yanayin da ya dace. Waɗannan su ne mahimman abubuwan fasaha don zaɓi:

1. Daidaiton diamita

Yanke zurfin ≤ 1/2 diamita kayan aiki don guje wa zafi da lalacewa. Lokacin sarrafa sassan alloy na bakin ciki na aluminum, yana da kyau a yi amfani da ƙaramin injin ƙarshen diamita don rage yankan ƙarfi.

2. Tsawon ruwa da adadin ruwan wukake

Yanke zurfin ≤ 2/3 na tsawon ruwa; don roughing, zaɓi 4 ko ƙasa da ruwan wukake don tabbatar da guntu sarari, kuma don kammala, zaɓi 6-8 ruwan wukake don inganta ingancin saman.

3. Juyin Halitta na kayan aiki

Ƙarfe mai sauri: babban ƙarfi, dace da yanke yanke

Carbide da aka yi da siminti: zaɓi na yau da kullun, daidaiton taurin da tauri

Ceramics/PCBN: Daidaitaccen mashin ɗin kayan masarufi, zaɓi na farko don taurin karfe

HIPIMS shafi: Sabon PVD shafi yana rage ginannen gefen kuma yana tsawaita rayuwa ta 200%

4. Gyaran siga na Geometric

kusurwar Helix: Lokacin sarrafa bakin karfe, zaɓi ƙaramin kusurwar helix (15°) don ƙara ƙarfin gefen.

kusurwar Tukwici: Don kayan aiki masu wuya, zaɓi babban kusurwa (>90°) don haɓaka tallafi

Injiniyoyi na yau har yanzu suna fuskantar ƙalubale da wata tambaya maras lokaci: yadda ake yankan ƙarfe mai santsi kamar ruwa mai gudana. Amsar ta ta'allaka ne a cikin tartsatsin hikimar da ke karo da juna tsakanin igiyar kadi da dabara.

[A tuntube mu don yankewa da hanyoyin magance cutter]

Lokacin aikawa: Agusta-17-2025